Spiral ductwork is a trusted choice that countless facilities have come to rely on. This innovative technology uses a spiraling method that connects metal strips to create seamless, durable ducting sections that can meet the needs of almost any application. Whether you’re looking for a ductwork solution for a commercial or industrial facility, AGI Fabricators has you covered. With our extensive selection of high-quality spiral ductwork products, we can help you find the perfect fit for your unique specifications.

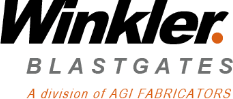

Types of Spiral Ductwork

At AGI Fabricators, we offer a range of spiral ductwork types to choose from, each with its own set of unique benefits based on its material properties. Here are the different types of spiral ducting materials to consider:

Galvanized Steel Spiral Ducting

Galvanized steel is the most common material used in spiral ductwork because of its lightweight and cost-effective characteristics. This option includes a zinc coating that offers increased resistance to corrosion and rust, making it suitable for indoor and outdoor installation.

At AGI Fabricators, our galvanized round spiral ducts, connectors, and hangers consist of steel and a galvanized coating, followed by an annealing process that further enhances the steel to prepare it for paint adhesion. We also offer galvanized perforated spiral ducts, with 23% open area. We manufacture these products with G-90 galvanized steel, an RL-1 spiral duct lock seam, and we ensure they comply with Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA) and American Society for Testing and Materials (ASTM) standards. These materials can withstand temperatures of up to 400 °F before the zinc coating wears off, but it’s best to avoid exposing them to temperatures exceeding 200 °F for extended periods.

Stainless Steel Spiral Ducting

Some applications with special requirements opt for stainless steel spiral ducting. For instance, exposed spiral ductwork may experience corrosion over time due to chemical wear. Other outdoor applications may also sustain wear resulting from rain and other conditions. In these cases, stainless steel offers superior corrosion resistance to maximize the ductwork’s longevity.

AGI Fabricators manufactures these ducting systems using 304 stainless steel alloy, an RL-1 spiral duct lock seam, and material construction in compliance with ASTM and SMACNA standards.

Paint Grip Spiral Ducting

Some applications may also require ductwork with painted surfaces to complement the surrounding architecture. Paint grip spiral ductwork consists of hot-dipped carbon steel sheet metal that has a double-sided zinc coating. We then heat treat the metal to convert the coating into a zinc-iron alloy that allows for paint application on the surface.

Aluminum Spiral Ducting

Aluminum spiral ducts consist of materials that combine lightweight construction with a high level of corrosion resistance.

Polyvinyl Coated Spiral Ducting

Many fume exhaust systems and underground ducting systems use polyvinyl-coated spiral ducting. It’s a reliable substitute for more traditional HVAC ducting and is particularly compatible with underground environments.

AGI Fabricators can manufacture any type of custom spiral ductwork in diameters ranging from four to 60 inches, with the standard usually falling around 10 feet. We also cut galvanized steel ductwork in gauges ranging from 20 to 26.

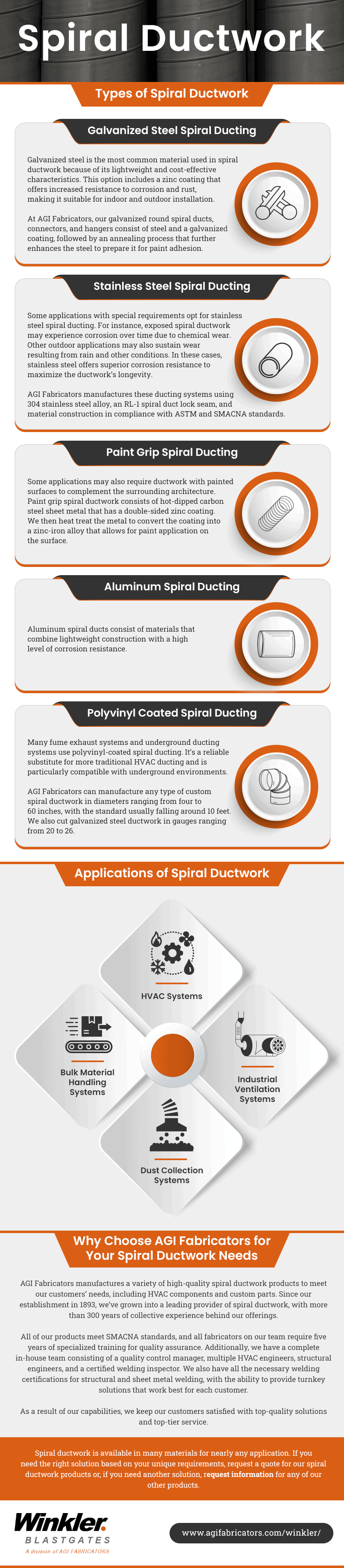

Applications of Spiral Ductwork

A wide range of applications use spiral ductwork for:

- HVAC Systems: Climate control systems often use spiral ducts to efficiently circulate cooled or heated air in facilities, maintaining a constant and evenly distributed airflow.

- Industrial Ventilation Systems: These systems frequently use spiral ductwork to remove different types of potentially harmful environmental toxins, including chemical fumes and microbes.

- Dust Collection Systems: These systems use spiral duct pipes and fittings for removing different types of particulate, including industrial dust, wood shavings, sawdust, and other types of byproducts to prevent health issues, equipment damage, and fire hazards.

- Bulk Material Handling Systems: Grain trucks, hoppers, and other material handling equipment often rely on spiral ducts for helping transport different types of solids.

The versatility of spiral ductwork also makes it popular in many types of settings, such as:

- Wood Shops

- Agricultural Facilities

- Industrial Manufacturing Plants

- Educational Institutions

- Churches

- Restaurants

- Offices

- Sports Facilities

- Warehouses

- Medical Facilities

- Retail Stores

- Entertainment Venues

- Community Centers

Why Choose AGI Fabricators for Your Spiral Ductwork Needs

AGI Fabricators manufactures a variety of high-quality spiral ductwork products to meet our customers’ needs, including HVAC components and custom parts. Since our establishment in 1893, we’ve grown into a leading provider of spiral ductwork, with more than 300 years of collective experience behind our offerings.

All of our products meet SMACNA standards, and all fabricators on our team require five years of specialized training for quality assurance. Additionally, we have a complete in-house team consisting of a quality control manager, multiple HVAC engineers, structural engineers, and a certified welding inspector. We also have all the necessary welding certifications for structural and sheet metal welding, with the ability to provide turnkey solutions that work best for each customer.

As a result of our capabilities, we keep our customers satisfied with top-quality solutions and top-tier service.

Learn More at AGI Fabricators

Spiral ductwork is available in many materials for nearly any application. If you need the right solution based on your unique requirements, request a quote for our spiral ductwork products or, if you need another solution, request information for any of our other products.